Compliance risks can arise at any stage in the supply chain — upstream, downstream, and within your organization — especially during periods of growth or transition. By integrating cloud labeling into your operations, you can streamline and shape your compliance strategy for suppliers, customers, and regulators, establishing a strong pivotal point for supply chain success.

Global manufacturing and distribution never stop advancing, and compliance measures evolve right alongside them as companies strive to ensure the legitimacy of their products while adhering to standards and regulations. Shifting customer demands, changing supplier relationships, diverse jurisdictions, new regulations and evolving company structures continuously emerge — often just as you have aligned with the previous challenge.

Business is built on a transformative framework, but your ability to respond to change is crucial for survival and success. Many companies take a slow and costly approach, investing significant time, effort, and money in adapting their supply chain processes and systems. Historically, these systems are siloed, unstable, and disconnected, making it difficult to meet compliance demands efficiently. They’re an increasingly heavy weight on large enterprises, while presenting potentially terminal risks to medium-sized and growing businesses.

Departments often scramble to push manual updates for label creation and artwork, while information flows through hundreds, or even thousands of suppliers and sites. In some cases, manufacturers print and ship packaging and labeling to trade partners, spending millions just to ensure parts, raw materials, and finished products make their way back to them or their customers correctly.

The global enterprise governance, risk, and compliance (eGRC) market size was valued at USD $38.35 billion in 2023. The market is projected to grow from USD 43.65 billion in 2024 to USD 111.31 billion by 2032, exhibiting a CAGR of 12.4% during the forecast period ¹.

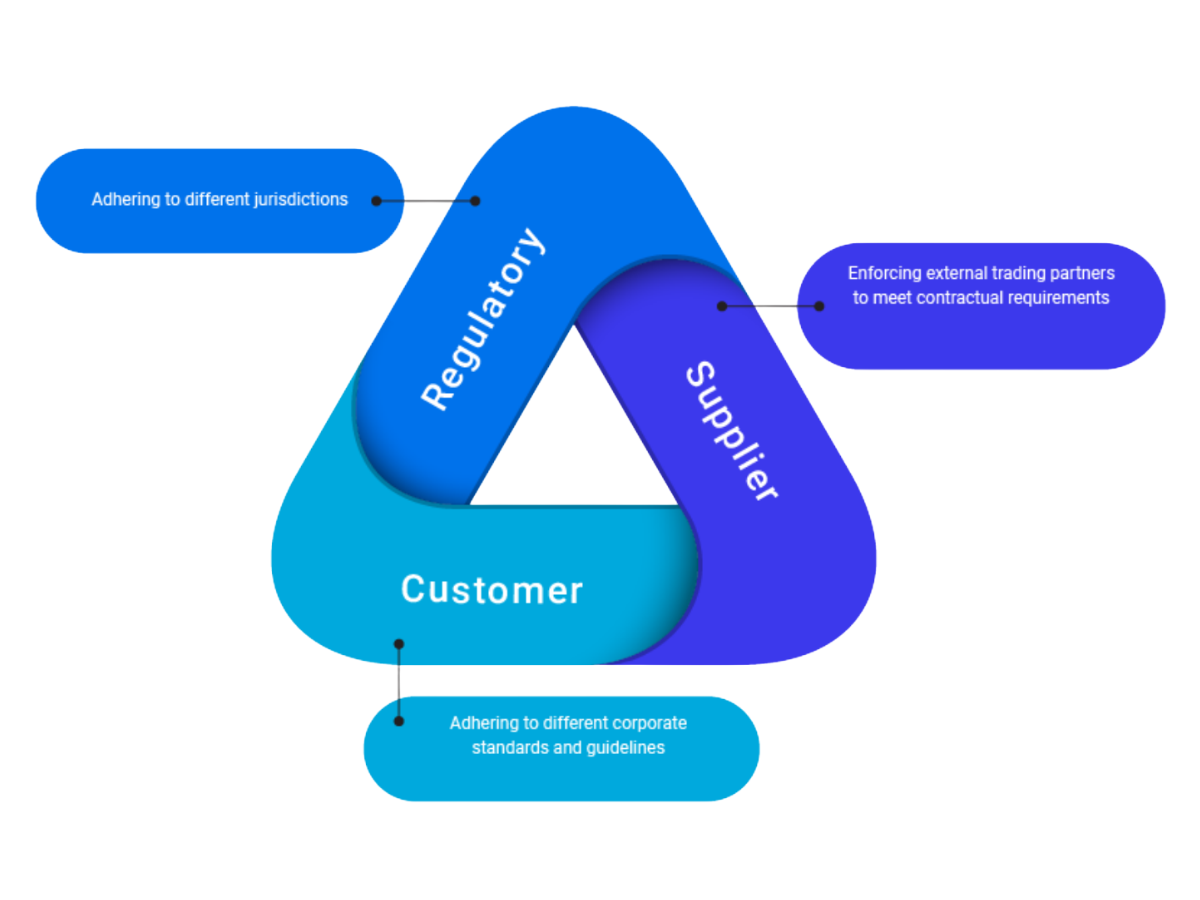

Beyond meeting regulatory demands, businesses now face increasing customer-driven compliance requirements, along with a growing need to ensure their suppliers meet compliance standards. This is the ‘Compliance Triangle’

Your organization must be compliant, but at what cost? As complex compliance demands continue to increase, the payout of managing the process and keeping up with each requirement — and the risks of falling behind — can quickly become both financially and logistically overwhelming. This calls for a better, more integrated, and modernized approach.

Compliance is often seen as synonymous with regulation. While regulations are undoubtedly a cornerstone of any compliance management framework, businesses are increasingly realizing that compliance risks extend far beyond regulatory boundaries.

This multitude of compliance considerations can be broadly separated into three categories — the faces of the Compliance Triangle:

These compliance considerations can be broadly categorized into the three faces of the Compliance Triangle:

In today’s globalized and decentralized economy — where operations cross international boundaries, organizations, and jurisdictions, and businesses depend on just-in-time and just-enough models — compliance acts as the glue that holds these inherently fragile frameworks together, strengthening a supply chain’s consistency, resilience, and accuracy.

All three categories are growing in prominence as supply chains become increasingly interconnected. To navigate this intricate ecosystem effectively, content and data management must serve as the central pivot point.

Let’s take a more detailed look at three faces of the Compliance Triangle.

Labeling, supported by accurate and reliable data, is essential for regulatory compliance, as it enables organizations to fully trace a product’s lifecycle. Regulatory compliance within the supply chain involves adhering to relevant laws, industry standards, and government regulations across various industries, often on a global scale. Labeling regulations are constantly evolving, and organizations must stay up to date with legislation to ensure that all business processes and data meet legal requirements and uphold consumer safety.

According to Gartner’s 2023 Future of Supply Chain Survey, 72% of high-performing supply chain organizations consider compliance to be a vital component of their risk management strategy ².

Increasingly, businesses must also prioritize compliance with Environmental, Social, and Governance (ESG) standards. This involves measuring a business’s impact on society, the environment, and how transparent and accountable it is, and requires companies to track and trace how materials and products are developed, shipped, and disposed of end-to-end.

Labeling, supported by true data sources as part of an interconnected network, is essential for attaining and maintaining regulatory compliance and enabling full product traceability.

Key obstacles to overcoming regulatory compliance are:

Supplier compliance is more than a legal or contractual obligation — it is a cornerstone of supply chain efficiency and business success. And the ability to onboard new suppliers quickly can be a make-or-break scenario.

Suppliers (old and new) need to adhere to contractual agreements, inbound requirements, quality standards, and ethical practices. It requires supplier organizations to regularly conduct audits, assessments, and performance monitoring to ensure agreed-upon conditions are met.

Specifically, within labeling, often suppliers aren’t providing what’s asked for as part of the Advanced Shipping Notice (ASN), creating inefficiencies. Furthermore, some companies either ship labels to suppliers or take a picture of the label/template for them to be recreated to send materials and products back. These approaches elongate timeframes, create waste and add cost, and so prompt identification and resolution are critical to maintaining a reliable supply chain.

Supplier compliance is increasingly difficult for businesses to manage. Despite its critical role in effective supply chains, a recent survey of Loftware customers found that almost 70% of large, global enterprises find supplier compliance challenging ³.

To achieve supplier compliance, interconnected systems are essential for streamlining processes and ensuring seamless communication and data sharing. By leveraging collaborative networks with suppliers, organizations can reduce risk, enhance operational agility, and maintain trust with customers and regulators alike.

Key obstacles to overcoming supplier compliance are:

Customer compliance involves meeting complex requirements related to product labeling, marking, and packaging, as well as ensuring that customer interactions and transactions adhere to contractual terms and conditions. This includes maintaining accurate records, labeling end products correctly for delivery, and promptly addressing product complaints, returns, recalls, or other issues.

Ensuring accurate and consistent label data, enabling real-time product identification, and meeting corporate and brand guidelines (especially within intra-company operations) are critical. Compliance with customer requirements and expectations is essential for building trust, preventing fines, and maintaining satisfaction.

Managing customer compliance is increasingly complex, as businesses often need to cater to the unique requirements of thousands of customers. These needs can vary widely based on customer type and market dynamics.

Businesses that address these challenges proactively can better maintain customer satisfaction, protect brand reputation, avoid hefty fines, and ensure operational efficiency.

In a staggering revelation, around 91% of surveyed logistics and supply chain companies agreed that they have paid fine and penalties in the last 12-month period⁴.

Key obstacles to overcoming customer compliance are:

Today’s supply chains need to have a consistent, connected approach to function, as complexity, globalization, and expectations from businesses and consumers have vastly increased.

Operators in all sectors must confidently manage compliance requirements around identification, labeling, packaging, and wider supply chain processes. Failing to meet requirements will lead to a range of serious consequences, including risk to consumer safety, brand status, fines for mislabeling and not meeting regulations, consequential delays, inability to enter new markets, and customer dissatisfaction.

According to Gartner Senior Research Director John Blake, the average cost of non-compliance has grown by 43% over the past nine years, with violations in pharmaceuticals alone exceeding $50 billion annually⁵.

The impact of non-compliance can be more wide-ranging than surface appearance may suggest. In fact, serious compliance breaches may result in potentially catastrophic outcomes, including strategic direction, hefty penalties, new market entry, and brand reputation, shaking the foundations of even the most established enterprise.

Overall impacts include:

In the three areas of the Compliance Triangle, specific consequences include:

Ultimately, many of these impacts overlap and feed each other. An error in labeling, when detected, could result in a pause of production for remediation or a product recall. Customers may be at risk due to mislabeled products, leading to negative publicity and regulatory scrutiny. Disrupted supply, combined with reputational damage, could see you passed over for a competitor in a certain region. This difficult to control collection of consequences is a compliance cascade.

To undertake potentially limitless impacts, compliance management must be proactive and pre-emptive. To prevent negative outcomes cascading across your operations, compliance management must embrace digital transformation.

A label is a passport of information. To achieve lasting, reliable compliance performance in your labeling, transformation at the information layer of your business is paramount.

A unified collaborative network is key to developing the vital connections your supply chain depends on, driving authenticity, compliance, and traceability at every stage.

By sharing the same universal infrastructure with all your stakeholders — from suppliers to partners, company locations, and customers — you can create the ability to manage content and exchange product identification standards, labels, data, and rules with ease, no matter the size or reach of your operation.

This standardized and centralized approach to label and packaging content allows you to quickly onboard new sites, manufacturers, suppliers, and distributors — typically within days — and integrate them painlessly across your enterprise.

A joined-up approach of your labeling and packaging within the supply chain will support and enhance the multitude of compliance variations occurring, whether upstream, downstream, within your company, or in the regulatory sphere.

A 2024 survey conducted by Loftware across more than 55 countries found that almost 85% of industry professionals are calling for greater connection and collaboration in global supply chains. Respondents agreed on the benefit of joining an ecosystem where partners across the supply chain can share access, data, and standards to ensure compliance, increase efficiency, and cut costs6.

Simplicity goes hand in hand with efficiency, reducing waste, and delivering significant time and cost savings.

Without a unified collaborative solution for all stakeholders, managing compliance in your supply chain may feel near impossible, slowing down your business, costing it money, affecting its reputation, and strategic agility.

This is where Loftware can help. Loftware’s end-to-end labeling solutions help customers make their supply chains more collaborative, meeting regulatory, customer, and supplier compliance while improving traceability and enabling authenticity.

A holistic strategy to compliance — one that includes detecting and pre-empting threats, manages huge volumes of data, and anticipates future changes — requires a unified approach to product identification, standards, artwork, data, and rules.

Loftware supports evolving compliance requirements globally, and helps companies save over $200 million in fines annually. Loftware provides flexible and scalable cloud-based solutions that can be easily integrated with sources of truth, ensuring consistent and accurate product identification across multiple locations, industry portals, and partners, avoiding disruptions.

Digital transformation of labeling and packaging within your supply chain must be seen as the balance point of the Compliance Triangle. By recognizing each area of compliance as one side of the same triangle, it becomes clear why a collaborative network, where customer, regulators, and supplier share a single source of the truth, is fundamental to the smooth running of future supply chains.

Sources Cited: